In the world of electronics, getting all the measurements right is very important, and one such measurement is the temperature. Yes, the temperature plays a crucial role in the working of all the electronic gadgets, failing which might result in some serious issues. So, how do these electronics really manage to maintain that crucial temperature? The answer is the RTDs. They are used in various industries like manufacturing and medical gadgets.

Now let's see about RTD first and then different RTD Sensor Types. To understand which exact sensor you will need for your necessity, there’s no need to be an engineer. Read along and we’ll guide you through the different types of RTDs and also the different elements used in manufacturing these. So by the end of this blog it’ll be easy to understand about sensors and which one suits your requirement.

But what is an RTD?

An RTD, or resistance temperature detector, is a device that measures temperature changes by checking how resistance varies as the temperature changes.

RTDs are different from thermocouples. They are designed to measure temperature with high accuracy and repeatability. The core principle behind them lies in the predictable increase in resistance that occurs as the temperature rises. The heat variations change the metal conductivity in a proper pattern, therefore, RTDs provide the correct readings by changing their electrical resistance in those different industries and applications as the temperature of the devices changes.

This change is then turned into an accurate temperature reading. How cool is that?

But do you know what makes RTDs even more interesting than the other devices? There is not a single type of RTD. They come in different types of RTDs, and also different elements that are used in the RTDs. But different types of RTD sensors have different uses and their drawbacks.

Types of RTDs

RTD sensors generally fall into two broad categories based on their construction: wire-wound RTDs and thin-film RTDs. Each of these has its unique benefits and best-use cases.

Wire-Wound RTDs

In wire-wound RTDs, the sensing element consists of a delicate coil of ultra-thin metal wire (usually platinum), which is encased in ceramic or glass.

Key Features:

- Highest Accuracy: These sensors are known for their precision, making them ideal for laboratory and industrial applications.

- Superior Stability: Their ability to maintain accuracy over long periods makes them suitable for high-precision environments.

- Fragility & Cost: Due to their delicate structure, they tend to be expensive and are more prone to vibration damage.

Thin-Film RTDs

Thin-film RTDs, on the other hand, are made by depositing a thin layer of metal onto a ceramic substrate. This layer is then etched into an electrical circuit pattern, ensuring a precise resistance value.

Key Features:

- Compact & Durable: Thin-film RTDs are highly resistant to mechanical shock and vibrations.

- Cost-Effective: Compared to wire-wound RTDs, they are more affordable while still maintaining good accuracy.

- Fast Response Time: Due to their small size, they react more quickly to temperature changes.

Comparing Wire-Wound vs. Thin-Film RTDs

| Feature | Wire-Wound RTDs | Thin-Film RTDs |

| Accuracy | High | Moderate |

| Stability | Excellent | Good |

| Durability | Less durable (prone to vibration damage) | Highly durable (shock-resistant) |

| Cost | Expensive | More affordable |

| Response Time | Slower | Faster |

Materials Used in RTD Sensors

The type of metal used in an RTD affects its performance, with platinum being the most popular choice. Other materials like nickel and copper are also used but have limitations.

Platinum RTDs

- Most widely used due to their accuracy and stability.

- Offers excellent corrosion resistance.

- Common in industrial and scientific applications.

Nickel RTDs

- Lower cost than platinum, but ages rapidly.

- Less accurate over time due to resistance drift.

Copper RTDs

- Highly conductive and inexpensive.

- Limited to lower temperature ranges ( appro 120°C max).

- Susceptible to oxidation and mechanical stress.

Choosing the Right RTD for Your Application

Selecting the right RTD depends on your specific needs:

- If you need high accuracy and stability, go for wire-wound platinum RTDs.

- If you want a cost-effective and durable option, thin-film RTDs are your best bet.

- If budget constraints are a concern, nickel or copper RTDs might be viable, though they lack long-term accuracy.

How JR Sensors Supports Precision Temperature Sensing

Reliable temperature measurement is crucial in various industries, from HVAC systems and home appliances to automotive and industrial automation. At JR Sensors, we understand the importance of precision, stability, and durability in temperature-sensing solutions.

While RTDs are widely used for high-accuracy applications, different industries require tailored sensor solutions. JR Sensors specializes in advanced temperature-sensing components, ensuring optimal performance in devices like air conditioners, water heaters, refrigerators, and industrial control systems. By focusing on quality materials, strict calibration processes, and cutting-edge sensor technology, JR Sensors helps businesses achieve efficient thermal management in their operations.

Read Next: Learn about the key difference between RTD and thermistors

Final Thoughts

RTDs are an essential part of temperature measurement in various industries, from manufacturing to healthcare. Whether you need precision, durability, or cost efficiency, there’s an RTD type that fits your needs. By understanding their differences, strengths, and applications, you can make an informed decision about which RTD sensor is best suited for your project.

Now it’s your turn! Are you looking for a reliable RTD solution for your application? Explore your options, consider your requirements, and choose wisely!

Frequently Asked Questions

1. What is an RTD sensor?

2. How do RTDs measure temperature?

3. What are the different types of RTD?

4. What is the best RTD configuration?

5. What materials are used in RTD sensors?

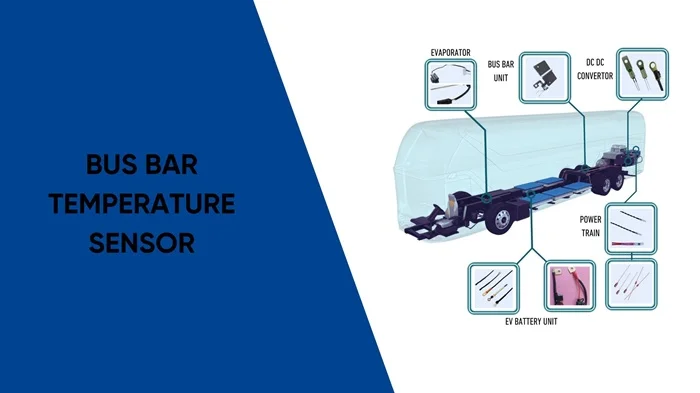

Busbar Watchdogs: The Tiny Sensors Preventing Massive Power Failures

Think of them as your system’s early warning system. Busbar temperature sensors silently protect power grids, data centers, and switchboards from overheating, fire, and failure. Discover why this small sensor plays a big role in electrical safety and uptime.

Beyond Specs: 5 Must-Know Factors When Choosing a Thermistor Sensor Manufacturer

Not all thermistor manufacturers are created equal. Whether you're building a medical device or a smart appliance, this guide breaks down the 5 key factors that ensure you get precision, reliability, and peace of mind.

Burnt Biscuits? Blame the Sensor – The Hot Truth About Your Oven’s Temperature Troubles

If your oven’s cooking like it’s got a mind of its own, your temperature sensor might be the silent saboteur. From half-baked casseroles to scorched cookies, we break down how this little sensor works, why it matters, and how to fix it—without losing your cool (or your dinner). A fun, practical guide that’s just as useful as it is digestible.