Beyond Specs: 5 Must-Know Factors When Choosing a Thermistor Sensor Manufacturer

Beyond Specs: 5 Must-Know Factors When Choosing a Thermistor Sensor Manufacturer

Deciding which thermistor sensor manufacturer is right is like looking for your soulmate. You want to avoid a supplier that vanishes without explanation, and especially one that sends defective sensors. If you are creating a medical device, constructing HVAC equipment, or trying to launch the next impressive coffee machine (which requires precise temperature control), a dependable thermistor manufacturer can help.

How do you decide on the right model? There are 5 important things to remember about them (you can skip the swiping):

Thermistor Matchmaking: 5 Factors to Consider While Choosing the Best Thermistor Sensor Manufacturer

1. Quality (Because Accuracy Isn’t Optional)

To be frank, a thermistor sensor that is off in its readings is not much use to anyone.

Having the best quality should always come first. An excellent manufacturer promises sensors with accurate specifications, good stability and dependable operation as time passes. If a company carries an ISO certification, that is a sign that they meets high-quality standards.

Try not to be taken in by anyone who acts all “trust me bro” with you. Ask to see the results of testing, technical details, and certificates. A reliable manufacturer will provide the paperwork, instead of just telling you about their abilities.

A reliable manufacturer has a successful history in industries that call for precision, such as aerospace, medical devices or automotive. You can feel safe sending your application to develop if companies can monitor rockets or patients with their sensors.

2. Customisation Capabilities (Because One Size Doesn’t Fit All)

Shoes that are three sizes too big are uncomfortable, and making do with a sensor that isn't perfect for your purpose is unfair, too.

The best thermistor manufacturers realise that every situation requires something unique.

Some products might need a non-standard resistance curve, a different lead wire length or an airtight package for tough situations. A leading manufacturer will immediately set to work, asking, measuring and building the product you order.

Feel free to ask if the Beta value, tolerance or packaging can be changed to suit us better.

Yes, and this is how we’ve provided the same result for customers like you,” tells you the company is a good choice.

3. Support & Communication (You’re Not Dating a Robot… Hopefully)

Communication plays an important role in every type of relationship, whether it is business or personal. Look for a company that replies to your emails, picks up your calls and carefully considers your needs (instead of nodding and sending any old thermistor).

In procurement, engineering or R&D, having a manufacturer with supportable staff can help solve problems quickly.

Bonus marks if they employ technical professionals who can help fix any issues, supply advice, or break down the information you get on product tags.

Watch out if it takes them a long time to answer, and all they say is one message with nothing helpful.

4. Lead Times & Delivery (Because Waiting Isn’t Fun, Unless It’s Pizza)

How do we make these ideas work in practice? Even the most incredible product is no good if your sensor maker delays its delivery for several months.

For projects on a schedule, it is especially important to keep delivery on schedule. Ask suppliers if they can supply you with lead time information, shipping choices and how they handle orders that are no longer available.

Some companies operate local facilities or make partnerships globally to prevent delays. Some businesses show their production plans clearly, so you can foresee production cycles and are less likely to be surprised.

Watch for a sign: the company promises delivery dates, but finally sends them much later. Nope. Having a person with receipts and schedules is important.

5. Cost (Not the Only Factor, but Still a Big One)

No problem, you are restricted by a budget. Still, don’t believe that cheap means good. Having thermistors fail early in your product’s life is a risk you should avoid by paying a little extra.

It’s better to buy from a manufacturer that offers quality components without charging too much, plus including a good warranty and tech support. Paying slightly more upfront can mean you spend less overall by having fewer complaints, returns and support troubles.

Ask the supplier if they have bulk price options, long-term supply arrangements and if there are cost-saving choices without any drop in performance.

A joke but still true: Any offer that is much better than competitors (such as a $0.02 sensor that could match the accuracy of NASA’s) fits better in fiction.

Bonus Round: Reputation Matters

If everything seems cloudy, read their reviews, ask other buyers for opinions and check if they have profiles on LinkedIn (we won’t judge you). When a thermistor sensor manufacturer is reputable, clients often return for more, testimonials are positive, and they often win industry awards.

It is also essential for a company to last a long time. Companies that last for decades must be doing things well. Such companies sometimes leave customers behind when things go wrong.

Final Thoughts

It may not be hard to find a reliable thermistor sensor manufacturer, but picking one is important. Quality, customisation, communication, delivery and cost are all parts of a machine that move together smoothly. If one person misunderstands or is off track, the rest of the system might fail.

Do your research, be brave when asking questions and don’t be okay with anything less than great for you.

You can now deliver the best care to your sensitive tech pieces.

Frequently Asked Questions

1. What is the most important factor when choosing a thermistor sensor manufacturer?

2. Can thermistor sensors be customised for specific applications?

3. How do I know if a manufacturer is reliable?

4. Is a lower price always better when sourcing thermistors?

5. What should I ask a manufacturer before placing an order?

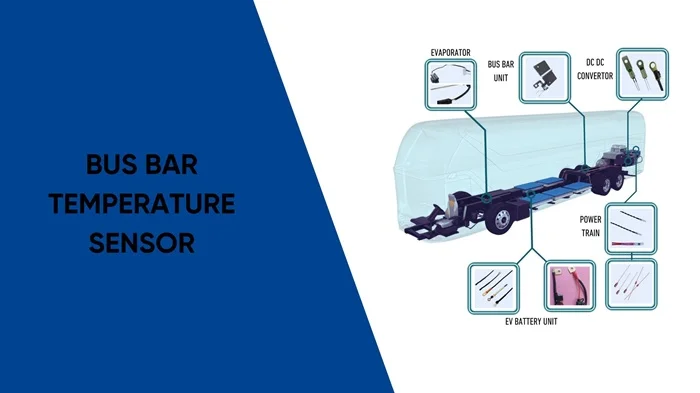

Busbar Watchdogs: The Tiny Sensors Preventing Massive Power Failures

Think of them as your system’s early warning system. Busbar temperature sensors silently protect power grids, data centers, and switchboards from overheating, fire, and failure. Discover why this small sensor plays a big role in electrical safety and uptime.

Beyond Specs: 5 Must-Know Factors When Choosing a Thermistor Sensor Manufacturer

Not all thermistor manufacturers are created equal. Whether you're building a medical device or a smart appliance, this guide breaks down the 5 key factors that ensure you get precision, reliability, and peace of mind.

Burnt Biscuits? Blame the Sensor – The Hot Truth About Your Oven’s Temperature Troubles

If your oven’s cooking like it’s got a mind of its own, your temperature sensor might be the silent saboteur. From half-baked casseroles to scorched cookies, we break down how this little sensor works, why it matters, and how to fix it—without losing your cool (or your dinner). A fun, practical guide that’s just as useful as it is digestible.