AC Temperature Sensors Manufacturer

Improve Your Air Conditioning Systems with Precision NTC Temperature Sensors

Improve Your Air Conditioning Systems with Precision NTC Temperature Sensors

Our NTC temperature sensors are designed for different air conditioning systems, making sure everything runs smoothly and reliably. They work well with Window ACs, Tower ACs, Split ACs (both Inverter and Non-Inverter), AHUs, and Chillers.

This sensor is ideal for measuring the surface temperature of various components such as IGBT, MOSFET, and heatsinks. It ensures accurate temperature readings for critical components.

This sensor is coated in epoxy to ensure durability and resistance to environmental factors. It is perfect for measuring ambient temperatures within the air conditioning system.

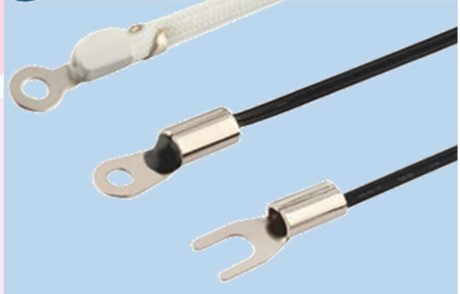

This sensor is potted with high moisture protection epoxies and encased in a metal cap. It is designed to measure the temperatures of critical components such as the AC coil and compressor in challenging environments.

These assemblies feature multiple sensors potted in epoxy, designed for applications where multiple temperature measurements are required simultaneously. The various construction types cater to different needs and conditions.

.jpg)

Make your air conditioning system more efficient and dependable with our top-notch temperature sensors.

Reach out to JR Sensors today to see how we can help boost your AC performance and keep your space comfortable.