For instance, all of a sudden, there is a loud boom: the lights flicker, then everything turns black. A transformer just blew up! You know that this is not a small thing; you probably have seen or heard about it. Transformers are very important for electrical power distribution; damage/preventive maintenance is crucial, however, as they fail so dramatically.

But what causes a transformer to blow up in the first place? One of the most important reasons would be transformer inrush current: that sudden, very high surge of current when the transformer is switched at first. Fortunately, such failures may be avoided with NTC thermistors, and it's a good thing because power systems can continue to run well. Let's get into it!

Why Does a Transformer Blow?

Transformers are very strong and extremely sensitive devices in the regulation of voltages in any electrical scheme. A transformer blowing can lead to consequences as slight as a temporary loss of power or as serious as destruction in some industrial or residential sectors.

These are the most common reasons for transformer failure:

Transformer Inrush Current

This is one of the major causes of transformer failures. When it is turned on, a transformer experiences an instantaneous high surge current called inrush current. The inrush current occurs because the magnetic core of the transformer needs to first be magnetized before it can reach a stable operating state.

The normal operating current can be relatively low compared to the inrush current. It can be anywhere from 10 to 20 times higher!

This sudden rise in current places stress on the transformer windings and insulation and finally results in overheating and possible failures.

A high level of inrush could also damage circuit breakers, fuses, and relays, which can lead to a second electrical failure.

Overloading

If a transformer is stressed way beyond its capacity to carry a load, it becomes hot. This excess heat degrades the insulation, leading to short circuits and internal arcing that would eventually result in a blown transformer.

Lightning Strikes & Power Surges

In case of a direct lightning strike or sudden rise in voltage, the transformer will outrightly fail. This is why surge protection is a must!

Internal Short Circuits

Internal short circuits could result from aging transformers or manufacturing defects, where the electrical current bypasses its intended circuit pathway, creating excessive heat that ultimately leads to transformer damage.

Poor Maintenance & Aging

And that brings us to the second cause of transformer failure-poor maintenance. The lifetime of transformers gets consumed naturally, and without regular inspections and maintenance, they become more susceptible to failures because of dust, moisture, or weakened insulation.

Now that we know what causes transformer failure let us consider how NTC thermistors provide a solution, especially concerning inrush current.

Understanding Transformer Inrush Current

Before we look for solutions, let's simplify the definition of transformer inrush current. When a transformer is switched on, the core requires some time to build the magnetic field. During this period, the transformer allows a very high initial current to flow; this is termed inrush current.

Transformer Inrush Current Calculation

Inrush current is influenced by several variables:

- The size of the transformer

- The point in the AC cycle when the transformer is switched on

- Residual magnetism in the transformer core

The transformer inrush current calculation formula generally relies on the following:

Iinrush=VpeakZimpedanceI_{\text{inrush}} = \frac{V_{\text{peak}}}{Z_{\text{impedance}}}

Where:

- IinrushI_{\text{inrush}} = Inrush current

- VpeakV_{\text{peak}} = Peak voltage of the AC supply

- ZimpedanceZ_{\text{impedance}} = Transformer impedance

And if you don't want to go through the trouble of picking up the calculator and doing your math, the secondary option for calculating the inrush current is to just feed the specs into a transformer inrush current calculator that could give you an approximate inrush current. Such calculators help engineers in designing circuits that are capable of handling and limiting the inrush current.

But wouldn't it be great if inrush current control could be kept simple and automatic? NTCs are the answer!

How NTC Thermistors Solve Transformer Inrush Current Issues

What Is an NTC Thermistor?

The definition of an NTC thermistor, or Negative Temperature Coefficient thermistor, is that it is a temperature-sensitive resistor where resistance is lowered with an increase in temperature.

- At startup (cold state) → High resistance → Limits inrush current

- During normal operation (warm state) → Low resistance → Allows normal current flow

Here, these characteristics make NTC thermistors the perfect answer for all jobs regarding handling transformer inrush current!

How NTC Thermistors Work in Transformers

- Powering the transformer on: On application of electrical power to the transformer, the thermistor offers high resistance at cold temperatures, thereby limiting the inrush current into the transformer.

- Transformer stabilization: Gradually, during the power-on phase, the resistance of the thermistor decreases as it heats up, permitting the normal operating current to flow.

- Safe, controlled power flow: In this way, a smooth transition from no-load to full-load is attained, avoiding undue voltage spikes, thereby protecting the transformer and allied electrical components.

Benefits of Using NTC Thermistors in Transformers

- Reduces Inrush Current: Safeguard against sudden surges of electricity by the transformer.

- Prevents the trips of Circuit Breaker: Avoids the nuisance breaker trips due to the higher inrush of the currents.

- Extended life of Transformer: Reduces the thermal and electrical stress that causes premature failure.

- Cost-Effective Solution: Small and cheap, and also very easy to integrate into the existing systems.

- Low Maintenance: Unlike others with the methods of current limiting, NTC thermistors require no maintenance in complexity.

JR Sensors: Mastering The NTC Like Never Before!

JR Sensors specializes in high-quality NTC thermistors, which are a dependable solution for the management of transformer inrush currents. Capacitated by technology, their thermistors effectively limit sudden current surges to prevent transformer failures, circuit breaker trips, and overheating. By their accurate temperature response and durability, JR Sensors thermistors contribute to the safety and longevity of power systems and, therefore, are important for efficient and stable transformer operation in various industrial and electrical applications.

Final Thoughts

What causes a transformer to blow? Though this destruction is generally attributed to inrush current, it may stress and damage the transformer over time.

Not allowing your transformer to live such a risky lifestyle, one might begin to consider an NTC thermistor as an easy, reliable, and cost-efficient way to limit inrush current and extend your electrical system's life cycle.

For anyone working with transformers-whether in industry, distribution, or even home electronics-Never forget about NTC thermistors. These thermistors are small, but they make a big difference in transformer safety!

Frequently Asked Questions

1. Why does a transformer blow?

2. What is the transformer inrush current?

3. How is the transformer inrush current calculated?

4. How do NTC thermistors help reduce transformer inrush current?

5. Are NTC thermistors necessary for all transformers?

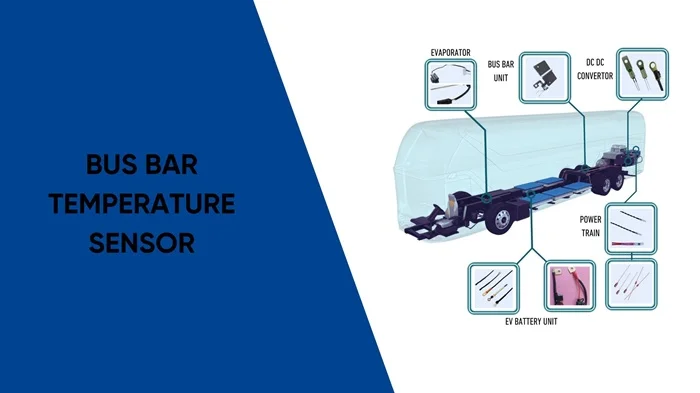

Busbar Watchdogs: The Tiny Sensors Preventing Massive Power Failures

Think of them as your system’s early warning system. Busbar temperature sensors silently protect power grids, data centers, and switchboards from overheating, fire, and failure. Discover why this small sensor plays a big role in electrical safety and uptime.

Beyond Specs: 5 Must-Know Factors When Choosing a Thermistor Sensor Manufacturer

Not all thermistor manufacturers are created equal. Whether you're building a medical device or a smart appliance, this guide breaks down the 5 key factors that ensure you get precision, reliability, and peace of mind.

Burnt Biscuits? Blame the Sensor – The Hot Truth About Your Oven’s Temperature Troubles

If your oven’s cooking like it’s got a mind of its own, your temperature sensor might be the silent saboteur. From half-baked casseroles to scorched cookies, we break down how this little sensor works, why it matters, and how to fix it—without losing your cool (or your dinner). A fun, practical guide that’s just as useful as it is digestible.