What Is a Thermocouple? | Different Types of Thermocouple Sensors Explained

What Is a Thermocouple? | Different Types of Thermocouple Sensors Explained

What is a Thermocouple?

The thermocouple. Sounds like something out of a sci-fi movie, but it's quite an everyday handy little piece of equipment. A thermocouple is a sensor for the measurement of temperature, but its definition is deceptively simple-it's got a nifty trick up its scientific sleeve.

So, what is a thermocouple? It's a device that converts heat, or temperature, into electricity, the traditional senses. No, it is two different types of metal wires bonded at one end. When that junction is subject to heating or cooling, a small measurable difference in electrical voltage occurs. The voltage can then be used to derive the temperature of whatever it gets attached to.

In simplest terms, the thermocouple is a temperature sensor that produces a voltage corresponding to the temperature of its surrounding environment. Imagine a tiny heat detective sending signals when something is hot or cold.

What is a Thermocouple Sensor?

Very informative! You indeed have to show well that a sensor is a sensor. A thermocouple sensor is not different from a thermocouple in basic construction and principle, but the term emphasizes its purpose as a sensor. The 'thermocouple' sensor senses temperature changes and passes these changes in the form of electrical signals that can be easily measured and interpreted.

This is very helpful, from your kitchen stove to gigantic industrial machines. The primary thermocouple sensor assures the existence of no overheating or submerging into a certain temperature. The next time you check the temperature of an oven or water heater and find it suitable, give full credit to the thermocouple sensor, although it is silently doing its part behind the scenes.

How Do Thermocouples Work?

Okay, enough definitions and let’s get into the working of this cute little device. The basic principle at the heart of any thermocouple is the Seebeck effect. Well, never mind if you haven't encountered it before; we shall analyze it right now.

When two different metal parts are joined at one end and possess a temperature gradient, a tiny electrical voltage is induced in the metal parts- the Seebeck effect. Think of it as them "talking" through their heat input and generating a measurable voltage that can be converted to read temperature.

Now take copper and iron for example. The very junction of both metals where the two will be joined will be heated and that temperature difference between the hot and cold ends of the metals will produce a very minor voltage. The greater the temperature difference, the larger the voltage. The measure is then recorded by some thermometer or measurement system to yield an accurate temperature reading.

Pretty cool, eh? The whole thing's a miniature electricity generator that turns heat into measurable voltage, and all without bulky electronics, just metal wires and heat.

Different Types of Thermocouples

Just before you believe that they all are leaders in the same class, I tell you that a lot of them are differentiated types. Indeed, the standard types of thermocouples as those made of diverse combinations of metals are for measuring a variety of temperature ranges. And, these are the most well-known:

- Type K (Nickel-Chromium / Nickel-Aluminum)

This is a rock-star performance among all thermocouples. The affordable price and performance in a wide range of conditions make this the most widely employed type. Type K Thermocouples can measure a temperature of -270° to +1372°C, which makes them extremely versatile, from measuring cold to super-hot industrial processes.

- Type J (Iron / Constantan)

Yet another kind of thermocouple quite popularly used is the type J thermocouple. It has an excellent facility of measurement at lower temperatures ranging from -40 degrees Celsius to +750 degrees Celsius. The good thing about Type J is that it is one of the oldest types of thermocouples, yet it serves the purpose very well. But be careful, as it succumbs to high-temperature corrosion after a while.

- Type T (Copper / Constantan)

Type T thermocouples are the low-temperature performance champions. Their operation extends from -200°C to +350°C with high precision. When working through extremely low temperatures in cryogenic applications, you will love having Type T around.

- Type E (Nickel-Chromium / Constantan)

Type E is an excellent choice for very sensitive and small temperature range applications. It can measure from -200°C to +900°C with a high output signal for precision measurements.

- Type R and S (Platinum / Platinum-Rhodium)

They are the premium models of thermocouples. They are for use when extreme accuracy is needed in a high-temperature environment. Type R and S thermocouples are usually applied in laboratories and industrial applications that reach a temperature of 1600°C.

- Type N (Nickel-Chromium-Silicon / Nickel-Silicon)

Type N thermocouples are relatively new in the market and are designed to withstand high-temperature applications with improved stability. They serve rather well in applications requiring long-term reliability, such as furnaces or other industrial processes up to temperature levels of 1300°C.

Read next: Difference between thermocouple and thermistor

Thermocouple by JR Sensors

JR Sensors specializes in manufacturing high-grade temperature sensers. These products ensure accuracy and reliability across various industries, including automotive, energy, and manufacturing. By providing real-time data, JR Sensors helps maintain optimal performance and efficiency in critical applications.

Conclusion

So, what have we learned today? A thermocouple is a nifty little device that measures temperature by generating a small electrical voltage when two different metals are heated. Therefore, this device works on the principle of the Seebeck effect, and the output voltage is related to temperature. Very simple, right? But also incredibly applicable and vital in various spheres: from home appliances to industrial machines.

Now that you know how thermocouples work, as well as the different types available, you will be more and more perceptible throughout your life. These tiny little devices are everywhere, ensuring that all things remain safe, efficient, and at the proper temperature. Who knew that something so obsessed with could truly make significant differences?

Frequently Asked Questions

1. What is a thermocouple used for?

2. How accurate are thermocouples?

3. What are the different types of thermocouples?

4. What’s the difference between a thermocouple and a temperature sensor?

5. Can thermocouples be used in any environment?

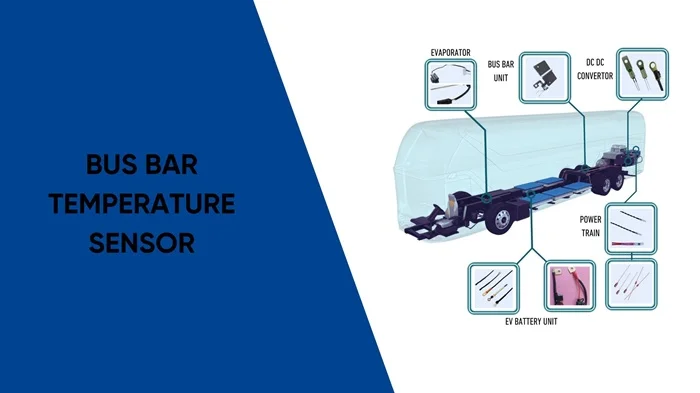

Busbar Watchdogs: The Tiny Sensors Preventing Massive Power Failures

Think of them as your system’s early warning system. Busbar temperature sensors silently protect power grids, data centers, and switchboards from overheating, fire, and failure. Discover why this small sensor plays a big role in electrical safety and uptime.

Beyond Specs: 5 Must-Know Factors When Choosing a Thermistor Sensor Manufacturer

Not all thermistor manufacturers are created equal. Whether you're building a medical device or a smart appliance, this guide breaks down the 5 key factors that ensure you get precision, reliability, and peace of mind.

Burnt Biscuits? Blame the Sensor – The Hot Truth About Your Oven’s Temperature Troubles

If your oven’s cooking like it’s got a mind of its own, your temperature sensor might be the silent saboteur. From half-baked casseroles to scorched cookies, we break down how this little sensor works, why it matters, and how to fix it—without losing your cool (or your dinner). A fun, practical guide that’s just as useful as it is digestible.