Electronics and most scientific applications, which come under the spectrum of industry-run processes, demand crucial temperature accuracies, which is an important parameter indeed. To ensure the safety (yes, safety first), quality of the manufactured products, their efficiency, and of course, the precision in that matter, selecting a good-quality temperature sensor is a very important task. Here, in the temperature sensors, there are 3 most commonly used ones. And these happen to be the RTDs, Thermistors, and Thermocouples.

According to the analysis of MarketsandMarkets, at a compound annual growth rate (CAGR) of 5.6%, the temperature sensor market is expected to reach USD 9.7 billion by 2029 from USD 7.4 billion in 2024. This calls out the urgency of precise, accurate temperature measuring devices across the range of electronic and industry-run processes.

Therefore, let us now take a thorough look at RTD vs Thermocouple vs Thermistor, understanding all their mechanisms, their practical applications. And let’s understand in which industrial process which sensor is best suited.

RTDs

RTD is a temperature sensor that works by changing its resistance when temperatures vary. The RTDs are usually made from materials like platinum, nickel, or copper, which makes them accurate and reliable. Platinum RTDs, such as the well-known Pt100, are especially good at providing consistent readings. You’ll often find these sensors used in various industrial, scientific, and medical settings.

Key Features of RTDs

* RTDs usually show a clear relationship between resistance and temperature, making it easier to understand the data.

* These sensors are very stable, making them a good choice for long-term monitoring in important industrial settings.

* RTDs are known for being pretty precise compared to other sensors, especially across a wide temperature range, from -200°C to 850°C.

Uses of RTDs

RTDs are commonly used in industries where getting precise and steady temperature readings is really important. They’re great for accuracy, but they can be a little costly and a bit fragile compared to tougher temperature sensors. Because of this, they might not be the best choice for industries that need something more durable or cost-effective. Here are some places where RTDs are used:

- Making Food and beverages industry

- Incubators and other medical equipment.

-Controlling and following up on the chemical productions and other industrial processes.

- Heating, ventilation, and air conditioning systems

Thermocouples

When 2 different metal alloys are combined at the junction, we have a tiny and handy thermocouple.

This junction produces the voltage, which is later used to detect temperature changes when it experiences a temperature change. The thermocouples are tough, cheaper, and, very importantly, handle a very wide range of temperatures.

Key Features of Thermocouples

* Thermocouples are ready to measure a wide range of temperatures, which happens to be the temperature as low as -200 degrees Celsius to as high as 2500 degrees Celsius, depending on the type, like Type K or Type J.

* They tend to be cheaper than RTDs and thermistors.

* Thermocouples are tough and can handle rough conditions like pressure, vibrations, and corrosive environments.

Uses of Thermocouples

Thermocouples are pretty quick to respond and can work well in tough environments. The other temperature sensors might fail. Because they’re tough and can measure a wide range of temperatures, thermocouples are found in a very big range of industries:

- Household appliances like ovens and water heaters, and many more day-to-day appliances.

- Power-generating places

- Automotive factories

- Metal processing industries

- Aerospace, and

- Petrochemical

Thermistors

Thermistors are temperature sensors that change their resistance as the temperature changes. They’re made from ceramic or polymer materials, unlike RTDs. The way their resistance changes isn’t a straight line; it varies a lot with temperature shifts.

Key Features of Thermistors

* They usually work well in a range from -50 to 150 degrees Celsius, but some special types can handle more extreme temperatures.

* They react quickly to small temperature changes, which is great for applications that require precise readings within a specific range.

* Thermistors usually cost less than RTDs, making them a popular choice for everyday products.

Uses of Thermistors

Thermistors are really sensitive, but their non-linear behavior and narrower temperature range make them not as flexible as RTDs or thermocouples in some industries. They're great for situations where you need high sensitivity across a limited temperature range, like:

- Consumer electronics, like battery monitoring in smartphones.

- Medical devices, such as thermometers

- Temperature control in cars

- Environment monitoring

Read Next: Difference between thermistor and thermocouple

RTD vs Thermocouple vs Thermistor: A Comprehensive Guide to Measuring Temperature Accurately

To figure out which temperature sensor works best for your needs, it's important to understand the differences between thermistors, thermocouples, and RTDs. Here’s a straightforward comparison of RTDs, thermocouples, and thermistors based on some key factors.

| Factor | RTD | Thermocouple | Thermistor |

| Accuracy | High (±0.1°C) | Moderate (±1°C to ±2°C) | High (for small ranges) |

| Response Time | Slower | Fast | Very fast |

| Temperature Range | -200°C to 850°C | -200°C to 2500°C | -50°C to 150°C |

| Durability | Fragile | Highly durable | Less durable |

| Cost | Expensive | Affordable | Most cost-effective |

| Linearity | Linear | Non-linear | Highly non-linear |

Which Temperature Sensor Should You Choose?

It all comes down to what you need:

Want high accuracy? Then, go with an RTD.

Looking for something tough and quick? Then, a Thermocouple is the way to go.

Need an affordable, sensitive sensor for small temperature ranges? Then, check out a Thermistor.

For industries where precision matters and you need something that lasts, RTDs are your best bet. If you're in a tough environment or need to deal with really high or low temperatures, thermocouples are great. For everyday gadgets and medical devices, thermistors usually work best.

Wrapping Up

Picking the right temperature sensor really matters for keeping things running smoothly and safely while maintaining product quality. Whether you need a precise RTD, a tough thermocouple, or a budget-friendly thermistor, knowing how they differ will help you make a smart choice. And that sums up the discussion about RTD vs thermocouple vs thermistor.

At JR Sensors, we focus on making accurate thermistors and temperature sensors that you can count on. We provide cutting-edge solutions tailored for various industries—including automotive, HVAC, medical, and industrial automation—ensuring precise temperature control in every application.

Frequently Asked Questions

1. What is the difference between RTD and thermistors & thermocouples?

2. What is the difference between RTDs and thermocouples?

3. Are thermocouples a good choice for industrial applications?

4. How do RTDs and Thermocouples measure temperature?

5. Why do thermistors cost more than RTDs?

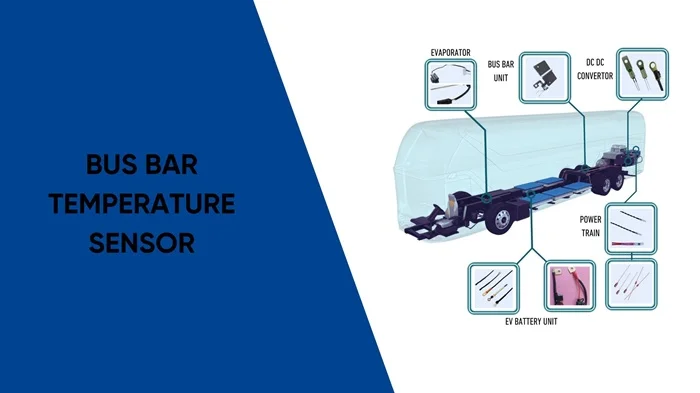

Busbar Watchdogs: The Tiny Sensors Preventing Massive Power Failures

Think of them as your system’s early warning system. Busbar temperature sensors silently protect power grids, data centers, and switchboards from overheating, fire, and failure. Discover why this small sensor plays a big role in electrical safety and uptime.

Beyond Specs: 5 Must-Know Factors When Choosing a Thermistor Sensor Manufacturer

Not all thermistor manufacturers are created equal. Whether you're building a medical device or a smart appliance, this guide breaks down the 5 key factors that ensure you get precision, reliability, and peace of mind.

Burnt Biscuits? Blame the Sensor – The Hot Truth About Your Oven’s Temperature Troubles

If your oven’s cooking like it’s got a mind of its own, your temperature sensor might be the silent saboteur. From half-baked casseroles to scorched cookies, we break down how this little sensor works, why it matters, and how to fix it—without losing your cool (or your dinner). A fun, practical guide that’s just as useful as it is digestible.