Ever walked into a room and instantly felt that “ahh, perfect temperature” vibe? Not too warm, not too chilly—just that cozy temperature that feels just right and comfortable. You know what that one thing is that has resulted in this? Nope, not your thermostat alone. But it's the sensors as well. The HVAC temperature sensors.

But before you judge that it's again some technical post and is getting boring. Wait. We are diving into the interesting info about these sensors that are being used in your home appliance, as well as the office, car, or server rooms. These make you or keep you comfortable.

From temperature sensors for HVAC systems in smart homes to very large industrial units in commercial complexes—these sensors happen to play a pivotal role in making sure things don’t go too hot or too cold. And let’s be honest—without them, we’d all be living in a constant state of sweater-on, sweater-off confusion, which, frankly, nobody has time for.

But how do these humble sensors actually work? What types are out there? And how do you even pick one that fits your needs? That’s exactly what we’re unpacking today.

Oh, and by the way—if you're on the hunt for a sensor for detecting & controlling the temperature, we've got a little insider gem for you at the end. (Hint: 100% customized design, no minimum order quantity. Sounds apt, right?)

Let’s get into it.

So... What Exactly Does an HVAC Temperature Sensor Do?

What does an HVAC temperature sensor actually do? Is it just there inside your air conditioning system doing nothing? Not even close.

Think of it as your HVAC system’s sixth sense. It’s constantly “checking” the room temperature, passing on the info to the control unit (a.k.a. the brain), and managing the inside environment.

These temperature sensors for HVAC systems are plugged into units like your thermostat, furnace, or air handler. They measure the ambient temperature and send real-time data to the controller. The controller then uses this data to make decisions. Like when to start blowing cool air or when to ease off because the temperature’s already perfect.

Let’s break it down even more:

- In smart homes, they’re like mini-geniuses that enable zone-based temperature control.

- In offices and commercial spaces, they’re synced with building automation systems. These setups don’t just regulate temperature based on time—they even factor in occupancy.

- And in data centers? They prevent overheating, which is like a big NOPE for servers.

So yeah, this emphasizes the growing need for HVAC temperature sensors in a gamut of industries..

Let’s be real—if your AC keeps blasting even when the room feels like Antarctica, chances are the sensor’s misreading the vibe. And guess who pays for that? Yep. You. Both in electricity bills and sanity.

Our friendly advice? Don't ignore the tiny stuff. They’re highly crucial for you to consider—especially if energy savings, comfort, and performance are on your checklist.

Types of HVAC Temperature Sensors (Yep, There’s More Than One)

Not all HVAC temperature sensors are created equal. It’s not a one-size-fits-all game here. Different environments, different needs, different sensor personalities. You’ve got to know what’s what before you throw one into your HVAC setup and hope for the best.

Here’s the lowdown on the main types you’ll come across.

1. HVAC Duct Temperature Sensors

These temperature sensors are inside your air ducts. Their job? Monitoring the air as it flows through your HVAC system. You’ll find these in both residential and commercial spaces. They're quiet, they’re accurate, and they’re all about that airflow.

2. HVAC Immersion Temperature Sensors

Now these sensors? Immersion sensors are inserted into pipes to measure the temperature of liquids—water, glycol, and so on—within your HVAC system.

These are used a lot in hydronic heating or chilled water systems.

3. HVAC Contact Temperature Sensors

These sensors attach directly to the surface of a pipe or unit, measuring the temperature via contact rather than diving in like immersion sensors.

They're super handy when you don’t want to penetrate the pipe system or when you're dealing with retrofits. Non-invasive, but still effective.

4. HVAC Cable Temperature Sensors

Flexibility is their middle name. These sensors can be wrapped around or installed in tricky spots where other sensors just won't fit. Ideal for unusual installations or tight corners that need temperature monitoring.

5. HVAC Outdoor Temperature Sensors

You guessed it—these live outside. They track the external air temperature and help your HVAC system anticipate what’s coming its way.

Why does that matter? Because smart systems use outdoor data to adjust indoor heating or cooling ahead of time. It’s predictive comfort.

6. Average Temperature Sensors

Now here’s a clever one. These don’t just read one point—they measure across a duct or zone to give you an average reading. Super helpful in large commercial HVAC systems where airflow and temperature can vary wildly from one point to another.

All these sensor types contribute something unique. So when choosing a temperature sensor for HVAC systems, don’t just grab the first one you see on the shelf. Ask yourself (or your HVAC tech): What are we measuring? Where? And how critical is the accuracy?

Don’t forget—materials matter too. Some sensors come armored. Some are sleek and minimal. Whatever the case, there’s a Thermistor, NTC sensor, or temperature probe out there that’s just right for your system.

Choosing the Right HVAC Temperature Sensor

Alright, so now you know these HVAC temperature sensors aren’t all the same. But how do you actually pick one?

Is it about price? Performance? Looks? But spoiler alert: not every sensor fits every system. So let’s break it down with some real talk. Here’s what you should keep an eye on:

1. Application – Where’s It Going?

First off, where’s this little device going to live? Inside an air duct? Submerged in water? Out on the building’s windy rooftop?

Each sensor is built with a purpose. You wouldn’t use a pool thermometer to measure coffee, right? So always match the sensor to the job:

- Use immersion sensors for fluids,

- Duct sensors for airflow,

- Contact sensors for surface readings,

- Outdoor sensors are when the weather’s part of the equation.

2. Temperature Range

Some environments are very harsh. Data centers, chemical plants, even your attic in mid-May.

If your sensor can’t keep up with the temperature extremes, it’s going to give up on you real quick. Always check the sensor’s operational range before you commit.

Pro tip: NTC thermistors are super sensitive and reliable in moderate ranges, which makes them apt for HVAC setups that demand precision.

3. Accuracy

This one’s non-negotiable. If a sensor’s reading is off by just a couple degrees, your entire system could be running inefficiently. That means higher bills and a whole lot of discomfort.

Accuracy at every measure isn’t just a luxury—it’s a must. Don’t settle for vague approximations when you can have pinpoint precision with a quality temperature probe or NTC sensor.

4. Response Time

Let’s say the room heats up fast. Your sensor should be able to notice and react fast, too. The right HVAC sensor should be quick on the uptake—especially in spaces where people are constantly moving in and out.

5. Compatibility

Your HVAC system is a combination of components, each from a different brand, with its own personality. So your sensor has to be compatible. Wiring, voltage, interface... all of that needs to match.

6. Customization – The Gold Standard

Sometimes off-the-shelf won’t cut it. You need something tailor-made. This is where JR Sensor’s temperature sensors come in. 100% customized product design with no MOQ (minimum order quantity). That’s rare, especially in the sensor space.

7. Durability

Some sensors will call it quits at the first sign of moisture, dust, or vibration. Others? Built like tanks. Make sure your sensor has a solid build—sealed housing, robust materials, maybe even some armored cabling.

Durability doesn’t just save you from sensor failure—it saves you from headaches. And unnecessary service calls.

JR Sensors – Thermistor & Temperature Sensors Manufacturer in India

Whether you need a classic NTC, a precision temperature probe, or a fully custom-built solution from scratch, JR Sensors has your back. From residential HVAC to critical industrial applications, we’ve mastered the art of accuracy at every measure—no matter the scale.

Let’s Wrap It Up

Picking the right temperature sensor for HVAC systems isn’t just about ticking boxes. It’s about understanding the environment, knowing your system, and choosing gear that actually makes sense. The right sensor keeps your space comfortable, your bills manageable, and your system humming like a happy engine.

Frequently Asked Questions

1. What is the temperature sensor for HVAC system?

2. What are the 4 types of temperature sensors?

3. What is HVAC temperature sensor control?

4. Which HVAC temperature sensor is used in AHU?

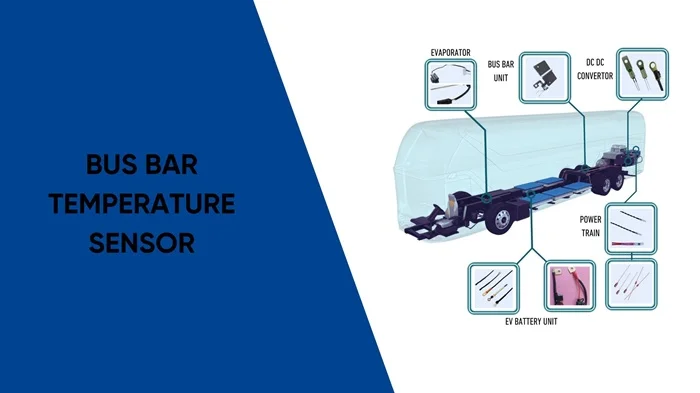

Busbar Watchdogs: The Tiny Sensors Preventing Massive Power Failures

Think of them as your system’s early warning system. Busbar temperature sensors silently protect power grids, data centers, and switchboards from overheating, fire, and failure. Discover why this small sensor plays a big role in electrical safety and uptime.

Beyond Specs: 5 Must-Know Factors When Choosing a Thermistor Sensor Manufacturer

Not all thermistor manufacturers are created equal. Whether you're building a medical device or a smart appliance, this guide breaks down the 5 key factors that ensure you get precision, reliability, and peace of mind.

Burnt Biscuits? Blame the Sensor – The Hot Truth About Your Oven’s Temperature Troubles

If your oven’s cooking like it’s got a mind of its own, your temperature sensor might be the silent saboteur. From half-baked casseroles to scorched cookies, we break down how this little sensor works, why it matters, and how to fix it—without losing your cool (or your dinner). A fun, practical guide that’s just as useful as it is digestible.