Difference Between NTC and PTC Thermistor: Key Comparisons & Benefits

Difference Between NTC and PTC Thermistor: Key Comparisons & Benefits

| Key Takeaways |

- NTC Thermistors: Decrease resistance with rising temperature, ideal for precise temperature sensing in medical devices, HVAC systems, and battery packs.

- PTC Thermistors: Increase resistance with rising temperature, providing effective protection against overcurrent and overheating in circuits, degaussing systems, and self-regulating heaters.

- Choosing the Right Thermistor: NTC thermistors are best for accurate temperature measurement, while PTC thermistors are suited for overcurrent protection and self-regulation.

- Applications: NTC examples include medical thermometers and HVAC systems; PTC examples include circuit protection and self-regulating heating elements.

- Benefits Comparison: NTC thermistors offer high sensitivity and a broad temperature range; PTC thermistors provide self-regulation and overcurrent protection.

Difference Between NTC and PTC Thermistor: Key Comparisons & Benefits

When choosing the right thermistor for your application, understanding the difference between NTC and PTC thermistor options is crucial. Both NTC (Negative Temperature Coefficient) and PTC (Positive Temperature Coefficient) thermistors are widely used in various industries, but their distinct characteristics make them suitable for different purposes. Let’s explore what sets them apart, how to determine which one suits your needs, and provide some ptc and ntc examples to illustrate their applications.

Understanding NTC and PTC Thermistors

What is an NTC Thermistor?

An NTC (Negative Temperature Coefficient) thermistor is a handy little device that plays a big role in managing temperature. As the temperature rises, its resistance drops, making it highly responsive to temperature changes. This sensitivity is what makes NTC thermistors a go-to choice for precise temperature sensing. You’ll often find them in medical equipment, where accuracy is critical, as well as in automotive sensors that monitor engine temperature. Even in household appliances, like your coffee maker or thermostat, NTC thermistors ensure everything runs smoothly by keeping temperatures in check.

Their ability to quickly respond to temperature fluctuations makes NTC thermistors indispensable in any application requiring accurate temperature monitoring. This reliability ensures that devices operate efficiently, safely, and within their designed temperature ranges, preventing potential malfunctions or damage.

What is a PTC Thermistor?

On the flip side, a PTC (Positive Temperature Coefficient) thermistor does the opposite—its resistance increases as the temperature goes up. This makes PTC thermistors perfect for protecting devices from overheating. They’re like the bodyguards of your electronics, stepping in when things get too hot. PTC thermistors are widely used in overcurrent protection, like in rechargeable batteries, to prevent them from overheating. You’ll also find them in degaussing circuits for TVs and in heating elements where they self-regulate to prevent burning out. Whether in your car, home appliances, or electronic devices, PTC thermistors are there to keep everything safe and functioning properly.

Additionally, PTC thermistors are commonly used in self-regulating heating elements found in devices like electric heaters or automotive seat warmers. As the heating element warms up, the PTC thermistor increases in resistance, reducing the current flow and preventing overheating. This self-regulating feature ensures consistent and safe operation, making PTC thermistors invaluable in applications that require controlled heating and protection against electrical faults.

Determining the Ideal Choice: PTC Thermistor vs NTC Thermistor

When choosing between NTC and PTC thermistors, it’s important to grasp the difference between PTC and ntc thermistors to make the right decision for your specific application.

If your project involves precise temperature measurement or control, an NTC thermistor is usually the way to go. These thermistors excel in environments where detecting small temperature changes is crucial, like in medical devices or automotive systems. For example, in a car's engine temperature gauge, an NTC thermistor’s ability to react quickly to temperature fluctuations ensures accurate readings, helping to maintain optimal engine performance.

On the flip side, if your main concern is protecting your circuits from overcurrent or preventing a device from overheating a PTC thermistor is more fitting. PTC thermistors are designed to increase their resistance when temperatures rise, which helps to limit current flow and prevent overheating. This makes them ideal for applications like rechargeable batteries, where they act as a safeguard, preventing the battery from getting too hot and potentially being damaged. Similarly, in devices like electric motors, PTC thermistors can step in to prevent overheating, ensuring the longevity and safety of the equipment.

By understanding the unique characteristics and PTC and NTC examples, you can select the right thermistor for your project. Whether you need accurate temperature sensing or reliable overcurrent protection, grasping the PTC thermistor vs NTC differences will help you make an informed choice that best meets your needs.

Benefits Comparison: PTC Thermistor vs NTC Thermistor

When comparing PTC thermistor vs NTC, it's essential to dive into the specific advantages each offers, ensuring you choose the right one for your needs:

NTC Thermistors:

- High Sensitivity to Temperature Changes: Understanding the difference between NTC and PTC thermistors highlights the high sensitivity of NTC thermistors. These components are incredibly responsive to even the smallest temperature fluctuations, making them ideal for applications where precision is essential. For instance, in medical devices or HVAC systems, accurate temperature readings are crucial. An NTC thermistor ensures reliable, real-time data, which is vital for optimal performance.

- Wide Temperature Range: Another key aspect of the difference between NTC and PTC thermistors is the wide operating temperature range of NTC thermistors. They function effectively across a broad spectrum, from very low to high temperatures. This versatility makes them suitable for various applications, including automotive temperature sensors and industrial equipment, where they need to withstand diverse environmental conditions.

- Ideal for Accurate Temperature Sensing and Control: Due to their high sensitivity and broad temperature range, NTC thermistors are preferred for systems requiring precise temperature monitoring and control. Whether it’s digital thermometers or home appliances, NTC thermistors play a crucial role in maintaining consistent performance and preventing overheating.

PTC Thermistors:

- Self-Regulating Properties: When comparing the difference between PTC and NTC thermistors, one notable feature of PTC thermistors is their self-regulating ability. As the temperature increases, PTC thermistors experience a sharp rise in resistance, which reduces current flow. This self-regulating feature is particularly beneficial in applications like degaussing circuits in televisions or self-resetting fuses, where it prevents excessive current from causing damage.

- Effective in Overcurrent Protection: Another important difference between PTC and NTC thermistors is the effectiveness of PTC thermistors in overcurrent protection. In the event of a current surge, a PTC thermistor increases its resistance, thereby limiting the flow of electricity. This makes it an excellent choice for safeguarding sensitive components in power supplies, chargers, and other electronic devices.

- Excellent for Applications Requiring a Fail-Safe Mechanism: PTC thermistors are renowned for their fail-safe mechanism. For instance, in rechargeable battery packs, PTC thermistors prevent overheating by reducing current flow when temperatures rise too high. This protective feature ensures the longevity of the device and mitigates potential hazards such as fires or explosions.

Understanding these distinctions allows you to make an informed decision on whether an NTC or PTC thermistor best suits your needs, whether it's for precise temperature control or robust circuit protection.

PTC and NTC Examples: Where Are They Used?

To give you a clearer picture, let’s explore some PTC and NTC examples to understand how these thermistors are applied across various industries:

NTC Thermistor Examples:

- Medical Devices Such as Thermometers: NTC thermistors are crucial in medical thermometers, where precise and rapid temperature measurement is essential. Their high sensitivity allows for accurate readings, ensuring that even minor fluctuations in body temperature are detected. This precision is vital in medical diagnostics, helping healthcare providers make informed decisions.

- HVAC Systems for Climate Control: In heating, ventilation, and air conditioning (HVAC) systems, NTC thermistors play a key role in monitoring and regulating temperatures. They ensure that the system maintains the desired climate by adjusting heating or cooling levels based on real-time temperature readings. This not only enhances comfort but also improves energy efficiency, leading to lower utility bills.

- Battery Packs to Monitor Temperature: NTC thermistors are used in battery packs, particularly in laptops, smartphones, and electric vehicles, to monitor and manage temperature. By providing accurate temperature data, they help prevent overheating, which could otherwise lead to reduced battery life or even safety hazards. This makes them an integral component in ensuring the reliability and safety of rechargeable batteries.

PTC Thermistor Examples:

- Overcurrent Protection in Electronic Circuits: PTC thermistors are often found in electronic circuits where they act as a safeguard against overcurrent conditions. When a surge occurs, the PTC thermistor increases its resistance, reducing the current flow and protecting sensitive components from damage. This feature is especially useful in devices like power supplies, chargers, and transformers.

- Degaussing Circuits in CRT Monitors: In older CRT monitors and televisions, PTC thermistors are used in degaussing circuits to remove residual magnetic fields. These fields can distort the picture on the screen, and the PTC thermistor helps neutralize them, ensuring a clear and stable display. While CRTs are less common today, this application highlights the specific and crucial role PTC thermistors play in maintaining visual quality.

- Self-Regulating Heaters in Automotive Systems: PTC thermistors are employed in self-regulating heaters, such as those used in car seat warmers or cabin heaters. As the temperature rises, the PTC thermistor increases its resistance, effectively controlling the heat output and preventing overheating. This self-regulating feature makes PTC thermistors ideal for applications where consistent and safe heating is required.

These examples highlight the versatility and importance of both NTC and PTC thermistors in various industries, from ensuring safety and precision in medical devices to protecting electronic circuits and enhancing automotive comfort. Whether it's for accurate temperature monitoring or reliable circuit protection, understanding the specific applications of these thermistors can guide you in selecting the right component for your needs.

JR Sensors: Your Engineering Solution Partner

When it comes to engineering solutions like NTC thermistors, JR Sensors stands out as a leader in the industry. With a reputation for delivering precision and reliability, JR Sensors offers cutting-edge temperature sensing and circuit protection components that meet the stringent demands of various sectors. Whether you're in automotive, medical, or industrial applications, JR Sensors' expertise ensures that you receive the best products tailored to your specific needs. Their commitment to quality and innovation makes them a trusted partner for companies seeking top-notch engineering solutions.

Conclusion: Understanding the Difference Between NTC and PTC Thermistor

In summary, the difference between NTC and PTC thermistors lies in their temperature response and applications. While NTC thermistors are ideal for temperature sensing and control, PTC thermistors are better suited for protection against overcurrent and overheating. When choosing between ptc thermistor vs ntc, consider your application’s specific needs. Understanding these differences, along with ptc and ntc examples, will ensure you select the right thermistor for your project, guaranteeing optimal performance and safety.

Frequently Asked Questions

1. What is the difference between NTC thermistors and PTC thermistors?

2. What is the difference between positive and negative temperature coefficient thermistors?

3. What is the difference between NTC and PTC fuses?

4. What is the difference between NTC and PTC inrush current?

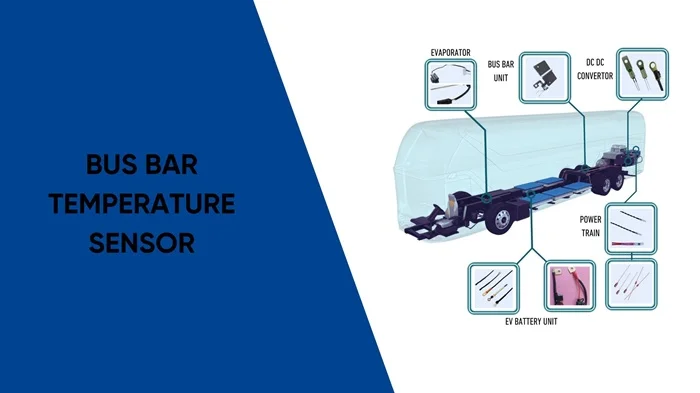

Busbar Watchdogs: The Tiny Sensors Preventing Massive Power Failures

Think of them as your system’s early warning system. Busbar temperature sensors silently protect power grids, data centers, and switchboards from overheating, fire, and failure. Discover why this small sensor plays a big role in electrical safety and uptime.

Beyond Specs: 5 Must-Know Factors When Choosing a Thermistor Sensor Manufacturer

Not all thermistor manufacturers are created equal. Whether you're building a medical device or a smart appliance, this guide breaks down the 5 key factors that ensure you get precision, reliability, and peace of mind.

Burnt Biscuits? Blame the Sensor – The Hot Truth About Your Oven’s Temperature Troubles

If your oven’s cooking like it’s got a mind of its own, your temperature sensor might be the silent saboteur. From half-baked casseroles to scorched cookies, we break down how this little sensor works, why it matters, and how to fix it—without losing your cool (or your dinner). A fun, practical guide that’s just as useful as it is digestible.