An NTC thermistor (Negative Temperature Coefficient thermistor) is one such temperature-sensitive component that finds applications in most industries owing to its ability to measure, control, and correct temperature variations. The basic working principle of an NTC thermistor is that its resistance decreases with an increase in temperature. This has been caused due to increased activity in charge carriers of different semiconductor materials, which comprise the thermistors such as metal oxides like nickel, cobalt, or manganese.

Their uses can be enumerated in health industries, for example in patient monitoring devices; in the automotive sector, for instance, to control the engine temperature, as well as in consumer electronics such as battery management systems. The NTC thermistor working principle deals with underlining variations of resistance as temperature changes and the derivation of these values to electrical signals for interpretation by external systems. Thus these thermistors are much smaller in size and more compact. The cost-effective and very sensitive features of these thermistors make them a worthy buy for several temperature-critical applications. No wonder, despite its non-linear response and other challenges, a thermality sensor remains the reliable and effective choice for accurate temperature measurement and control.

What is an NTC Thermistor?

The typical NTC thermistor is a resistor sensitive to temperature that reduces resistance when the temperature increases. On the contrary, PTC thermistors increase resistance as the temperature rises, but not NTC thermistors. This is what makes these thermistors applicable to temperature monitoring, measurement, or control applications. NTC thermistors are made mainly from metal oxides such as nickel, cobalt, or manganese and are found in healthcare, automotive, and intelligent consumer electronics applications. NTC thermistors’ workings are extremely sensitive, compact, and cost-effective and can work under conditions requiring high reliability, such as battery management, HVAC systems, and medical devices.

The NTC Thermistor Working Principle

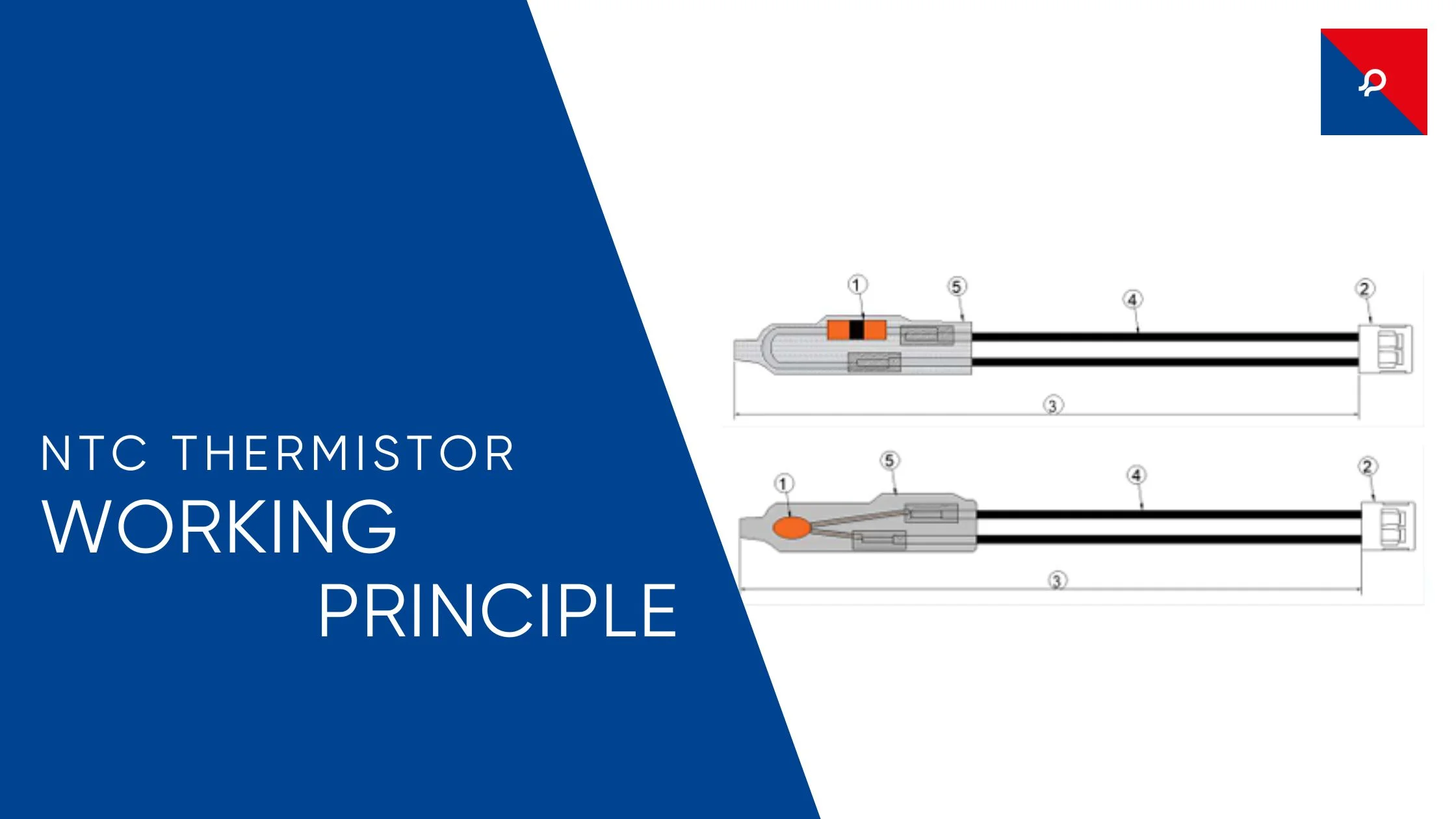

An NTC sensor working principle flows ahead because the amount of electrical resistance it possesses changes with thermal conditions. It is made by taking a combination of semiconducting materials such as metal oxides (nickel, manganese, or cobalt) and making them into a sintered ceramic-like structure. This is how it works:

Resistance-Temperature Relationship

- With temperature, the number of charge carriers (holes or electrons) in the semiconductor material increases. This added carrier density leads to higher electrical conductivity which reduces the resistance of the thermistor.

- For the rising temperature, there is an increasing number of charge carriers (holes or electrons) in the semiconductor material. This increased concentration of carriers increases the electrical conductivity and decreases the resistance that a thermistor experiences.

Current Flow

- Current flow is inversely proportional to resistance across the thermistor when a voltage is applied.

- The high temperatures cause the low resistance to allow more current to flow, so the device can notice and react to changes in temperature effectively.

Non-Linear Behavior

- The resistance-temperature relationship in an NTC thermistor is nonlinear, which means that the resistance decreases exponentially on the rise of temperature.

How Does an NTC Sensor Work?

A thermistor is a temperature-sensitive resistor; the NTC sensor working principle is based on the thermistor behavior that it has to measure and detect the temperature change. NTC sensors have found application in several industries because of their precision, fast response, and reliability in temperature measurement and control systems.

Temperature Detection

An NTC sensor consists primarily of the NTC (Negative Temperature Coefficient) thermistor. The thermistor senses the temperature variations by reduction in resistance with increasing temperature. Since the relation between temperature and resistance has a predictable nature, it makes the sensor give precise measurements for a certain defined range, which is beneficial to applications in HVAC systems, automotive electronics, and healthcare devices.

Signal Conversion

The alteration of resistance due to a temperature change can be converted into an electrical signal that can be linearized and processed by external systems (for example, microcontrollers, data loggers, or industrial control units) that interpret that external signal for calculating the exact temperature.

Feedback Control

An electrical signal is generated from the NTC sensor to furnish feedback for control mechanisms. For example, in an HVAC system, the sensor facilitates maintaining the ambient temperature by varying heating or cooling processes. In safety-critical applications such as medical devices or power systems, the sensor could optionally trigger alarms when overheated or terminate the temperature fluctuations.

Compact design, low cost, and high sensitivity NTC sensors are the smart ways of underlining operational efficiency and safety in temperature-sensitive systems.

Applications of NTC Thermistors

- Temperature Measurement

- Widely used in thermometers and temperature sensors.

- Overcurrent Protection

- Protects circuits by sensing excessive temperature rise.

- Automotive Sensors

- Monitors engine temperature and cabin climate.

- Consumer Electronics

- Ensures optimal performance in devices like chargers and batteries.

- Medical Equipment

- Used in incubators and patient-monitoring devices for precise temperature control.

Benefits of NTC Thermistors

- High Sensitivity

- Can detect minute changes in temperature.

- Compact Design

- Small size allows for integration into space-constrained devices.

- Cost-Effective

- Offers high performance at a low cost.

- Reliable Performance

- Delivers accurate readings over a wide temperature range.

Challenges with NTC Thermistors

- Non-Linear Response

- Requires calibration or compensation to ensure accuracy.

- Limited High-Temperature Range

- May not perform well in extremely high temperatures.

- Aging Effects

- Resistance may drift over time, requiring recalibration.

JR Sensors and Their Expertise in NTC Thermistors

JR Sensors is a well-known and big producer of high-quality temperature sensing solutions as it engages particularly in NTC thermistors and sensors. It carefully specializes in delivering precision and innovation to the market while manufacturing reliable and durable components for several industries, including automotive, healthcare, and industrial automation. They design thermistors to perform excellently in different challenging environments, hence being a perfect partner for advanced temperature sensing requirements.

JR sensors offer you modern technology and unparalleled customer support through which you can get shone from his exceptional temperature monitoring systems.

Conclusion

The NTC thermistor working principle is vital to modern temperature sensing, as it provides accuracy, reliability, and versatility in a wide range of applications. NTC thermistors decrease resistance in response to increased temperature and are therefore used to provide accurate and stable temperature readings. This property makes NTC thermistors ideal for monitoring and controlling temperature in a wide variety of applications like medical devices, automotive systems, consumer electronics, and HVAC systems.

They are so simple and inexpensive, yet they have excellent response times, improving performance and safety in complicated systems. For instance, NTC thermistors can maintain critical temperatures in medical devices, prevent overheating in electrical power systems, and regulate ambient conditions in automotive systems. Understanding the working principle of these thermistors enables their effective utilization for enhanced operational efficiency and safety in temperature-critical environments.

Frequently Asked Questions

1. What is the NTC thermistor's working principle?

2. What is the difference between NTC and PTC thermistors?

3. Where are NTC thermistors commonly used?

4. How do NTC sensors provide temperature readings?

5. What factors affect the accuracy of an NTC thermistor?

Burnt Biscuits? Blame the Sensor – The Hot Truth About Your Oven’s Temperature Troubles

If your oven’s cooking like it’s got a mind of its own, your temperature sensor might be the silent saboteur. From half-baked casseroles to scorched cookies, we break down how this little sensor works, why it matters, and how to fix it—without losing your cool (or your dinner). A fun, practical guide that’s just as useful as it is digestible.

Hot Stuff: Why Your Engine Can’t Live Without an Exhaust Temperature Sensor

Think exhaust sensors are just another car part? Think again. These tiny guardians track fiery exhaust temps, protect turbos, keep emissions in check—and even help you pass that dreaded test. Dive into the witty, down-to-earth guide on how EGT sensors silently save your engine (and your wallet) every day. Bonus: You’ll sound like a car guru by the end.

Tiny Tech, Big Impact: Inside the World of Medical Temperature Sensors

Discover how medical temperature sensors work, why they're crucial in healthcare, and how health sensors are transforming modern medical diagnostics. From wearable tech to high-precision devices, learn about the different types of temperature sensor medical devices used today.