NTC temperature sensors (Negative Temperature Coefficient), also known as NTC thermistors, are vital components in the realm of electronics. Their unique characteristics make them indispensable for various applications, contributing to enhanced performance and reliability. In this blog, we’ll explore the applications and advantages of NTC temperature sensors while shedding light on how JR Sensing, a leader in sensor technology, is making significant strides in this field.

Applications:

Temperature Monitoring in Electronics: NTC temperature sensors excel in precisely measuring and monitoring temperature changes in electronic devices. They are widely used in computers, servers, and other electronic systems to prevent overheating and ensure optimal performance.

Climate Control Systems: HVAC (Heating, Ventilation, and Air Conditioning) systems leverage NTC temperature sensors for accurate temperature readings. This application is crucial for maintaining comfortable indoor environments in homes, offices, and industrial settings.

Automotive Industry: NTC thermistors play a pivotal role in the automotive sector. They are integrated into engines, exhaust systems, and climate control units, ensuring efficient temperature regulation. This aids in optimizing engine performance and enhancing overall vehicle safety.

Medical Devices: In medical equipment, precision is paramount. NTC temperature sensors find applications in devices such as incubators, diagnostic equipment, and thermal therapy systems. Their ability to provide accurate temperature feedback is crucial for patient safety and device functionality.

Battery Management: Efficient battery management is essential for the longevity and safety of electronic devices. NTC temperature sensors are employed in battery packs to monitor temperature variations, preventing overheating and extending battery life.

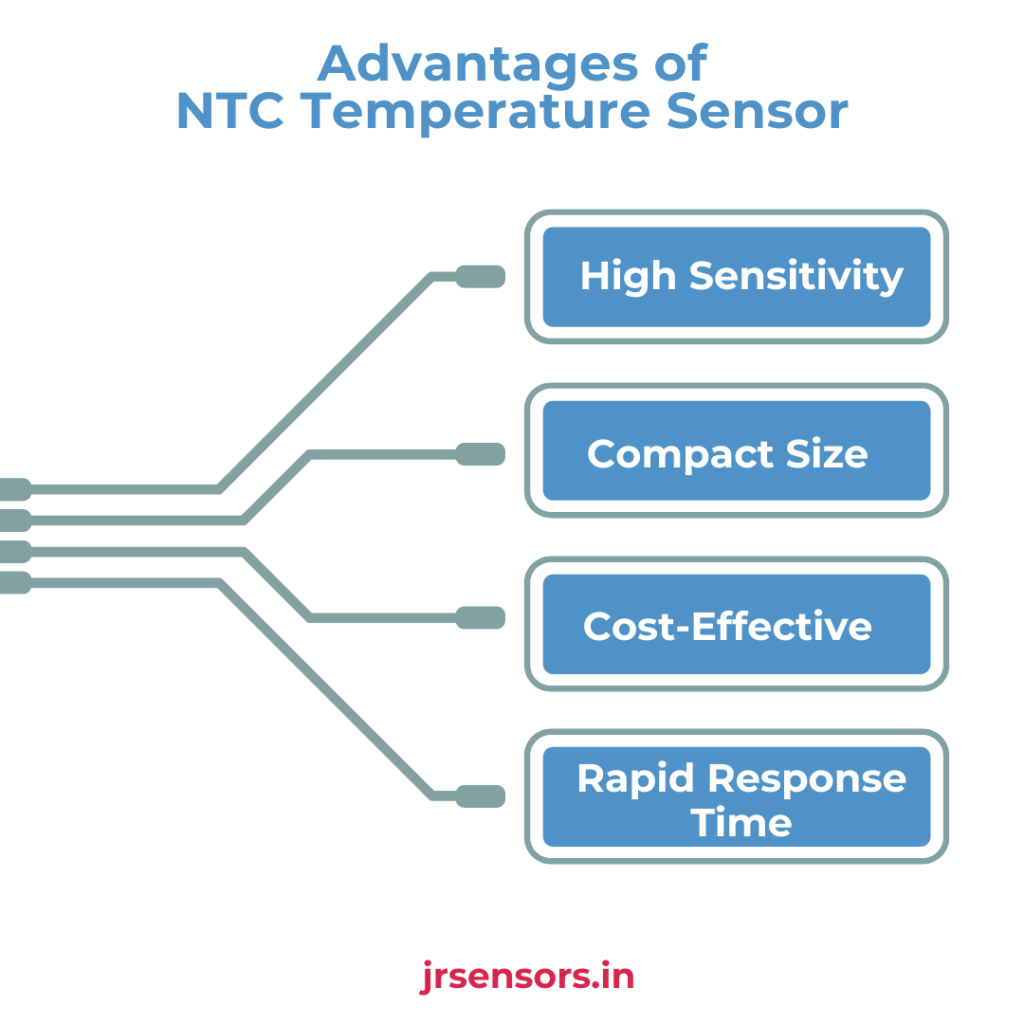

Advantages:

High Sensitivity: NTC thermistors exhibit high sensitivity to temperature changes, allowing for precise measurements. This characteristic makes them ideal for applications where accuracy is critical.

Compact Size: The compact size of NTC temperature sensors enables their integration into small electronic devices seamlessly. This versatility makes them suitable for a wide range of applications without occupying excessive space.

Cost-Effective: NTC thermistors offer a cost-effective solution for temperature sensing in comparison to some other temperature sensor technologies. This cost efficiency makes them a preferred choice for various industries.

Wide Operating Temperature Range: NTC temperature sensors have a broad operating temperature range, making them suitable for applications spanning from extremely cold to high-temperature environments.

Rapid Response Time: NTC thermistors exhibit a rapid response time to temperature changes, ensuring real-time monitoring and quick adjustments in electronic systems.

JR Sensing, a leading innovator in sensor technology, offers a diverse range of high-quality NTC temperature sensors designed to meet the stringent demands of modern applications. Here’s why JR Sensing stands out:

Quality Assurance: JR Sensing prioritizes quality, subjecting each NTC temperature sensor to rigorous testing to guarantee accurate and consistent performance.

Comprehensive Product Range: Whether for climate control systems, automotive applications, or medical devices, JR Sensing provides a comprehensive product range catering to various temperature sensing requirements.

Innovation: JR Sensing stays at the forefront of technological advancements, incorporating the latest innovations to enhance the capabilities of their NTC temperature sensors.

Conclusion:

The widespread applications and advantages of NTC temperature sensors underscore their significance in the electronics industry. JR Sensing, with its commitment to quality and innovation, plays a pivotal role in advancing sensor technology. As electronic devices continue to evolve, NTC temperature sensors from JR Sensing are poised to be at the forefront, ensuring efficiency, reliability, and precision in temperature monitoring across diverse applications.